From design to manufacturable reality — without the guesswork.

Relay Manufacturing helps teams move from CAD to real parts with engineering judgment, clear scope, and accountable execution — especially when the work is too important to leave to trial-and-error.

We focus on manufacturable, clearly-scoped work — with fast feedback and clear constraints.

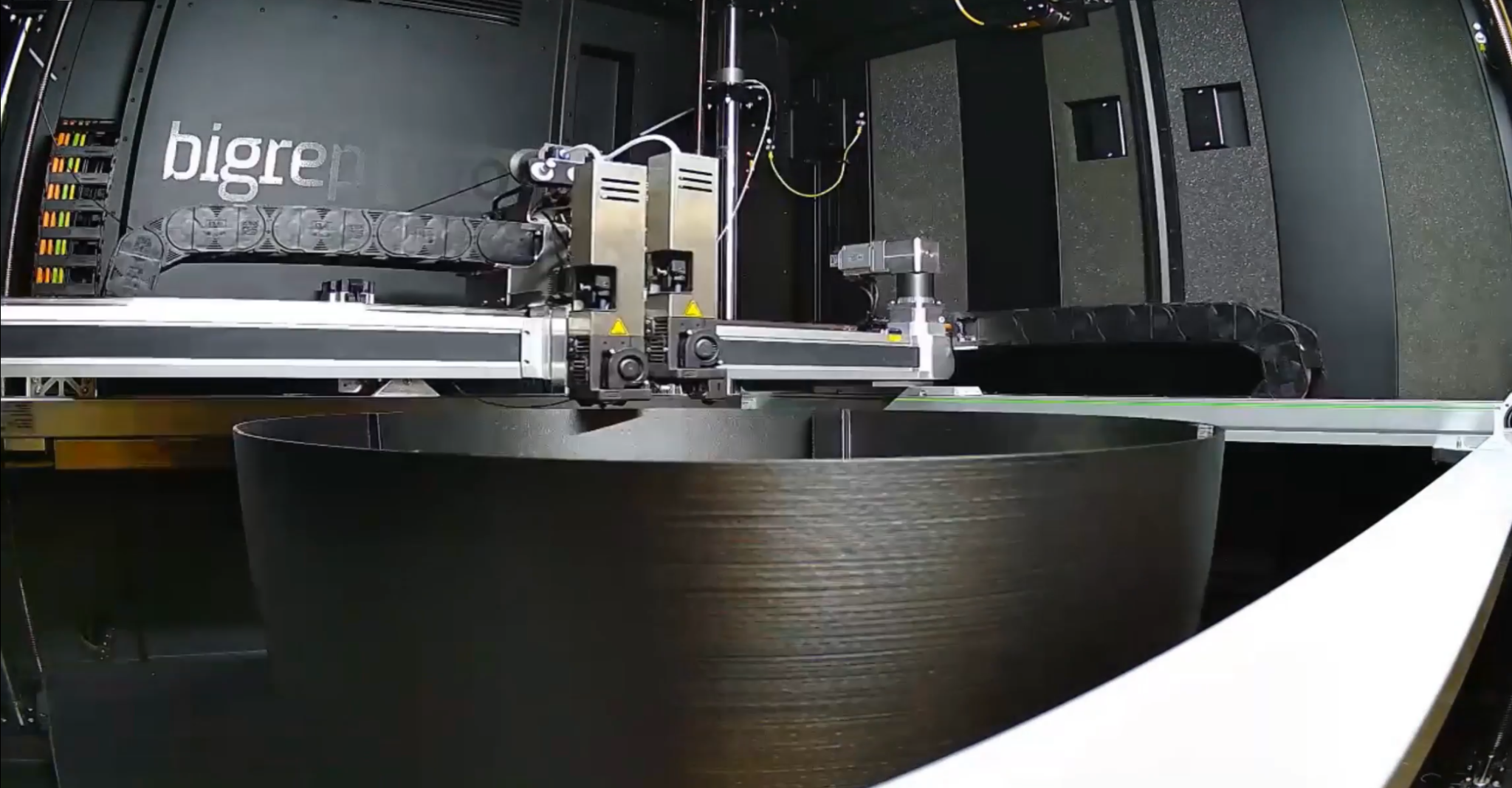

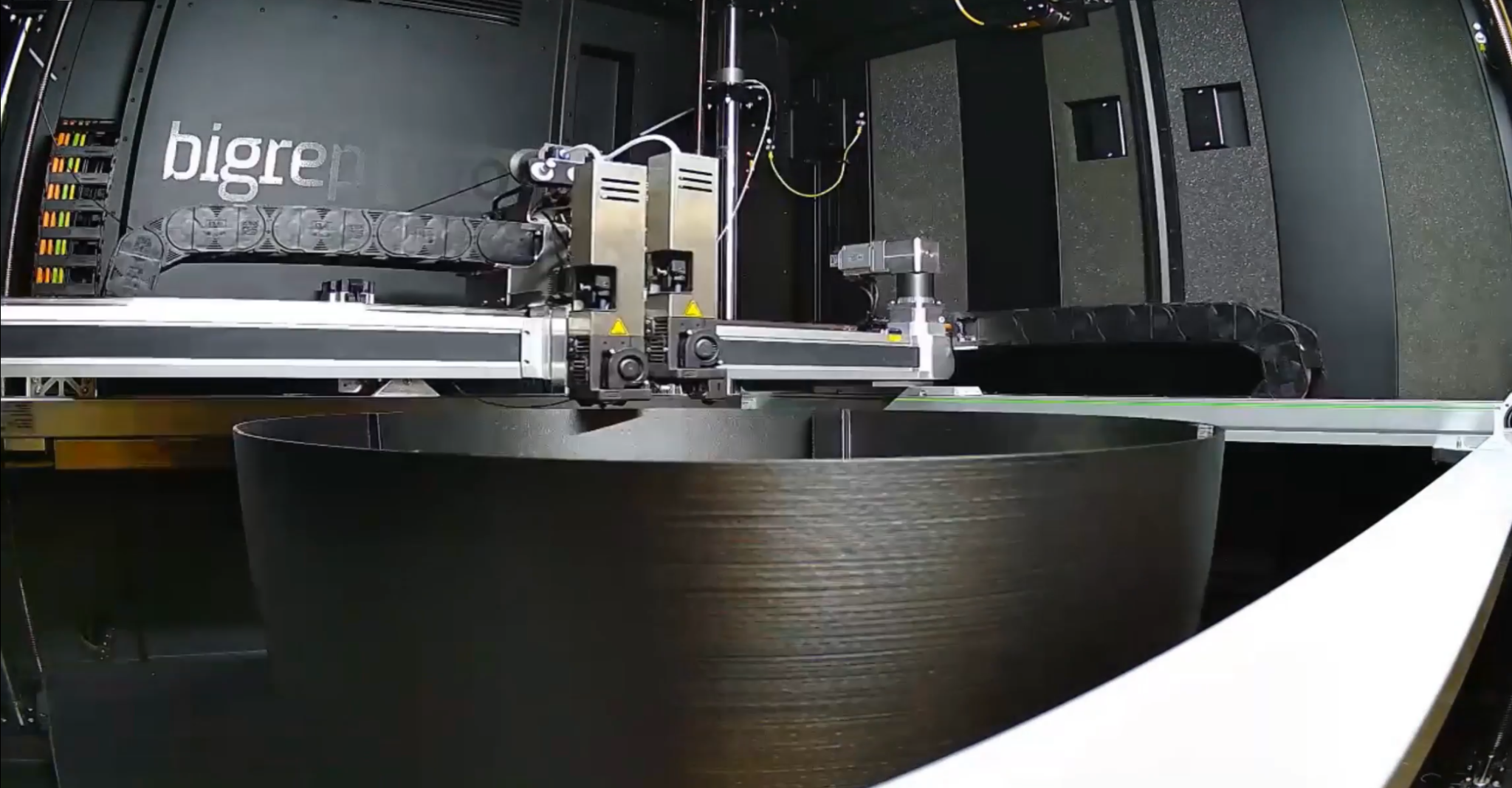

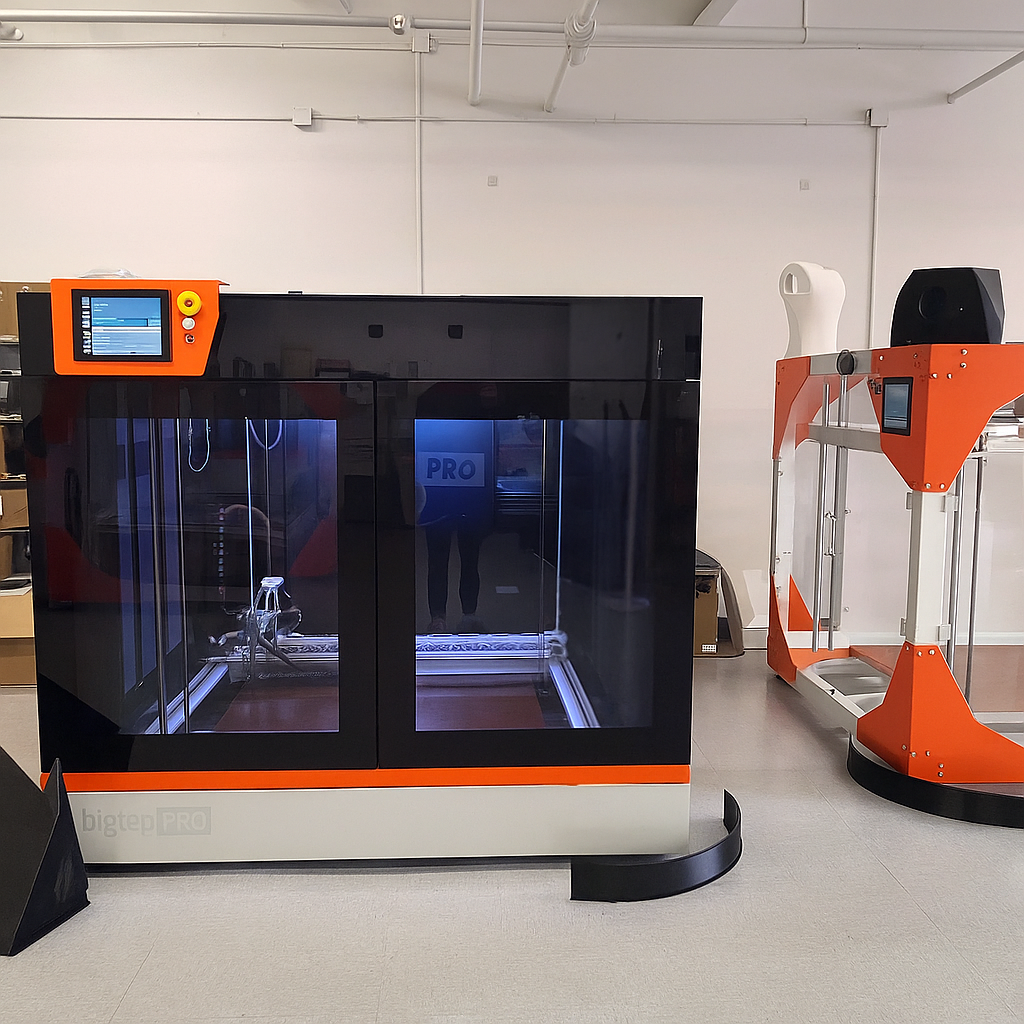

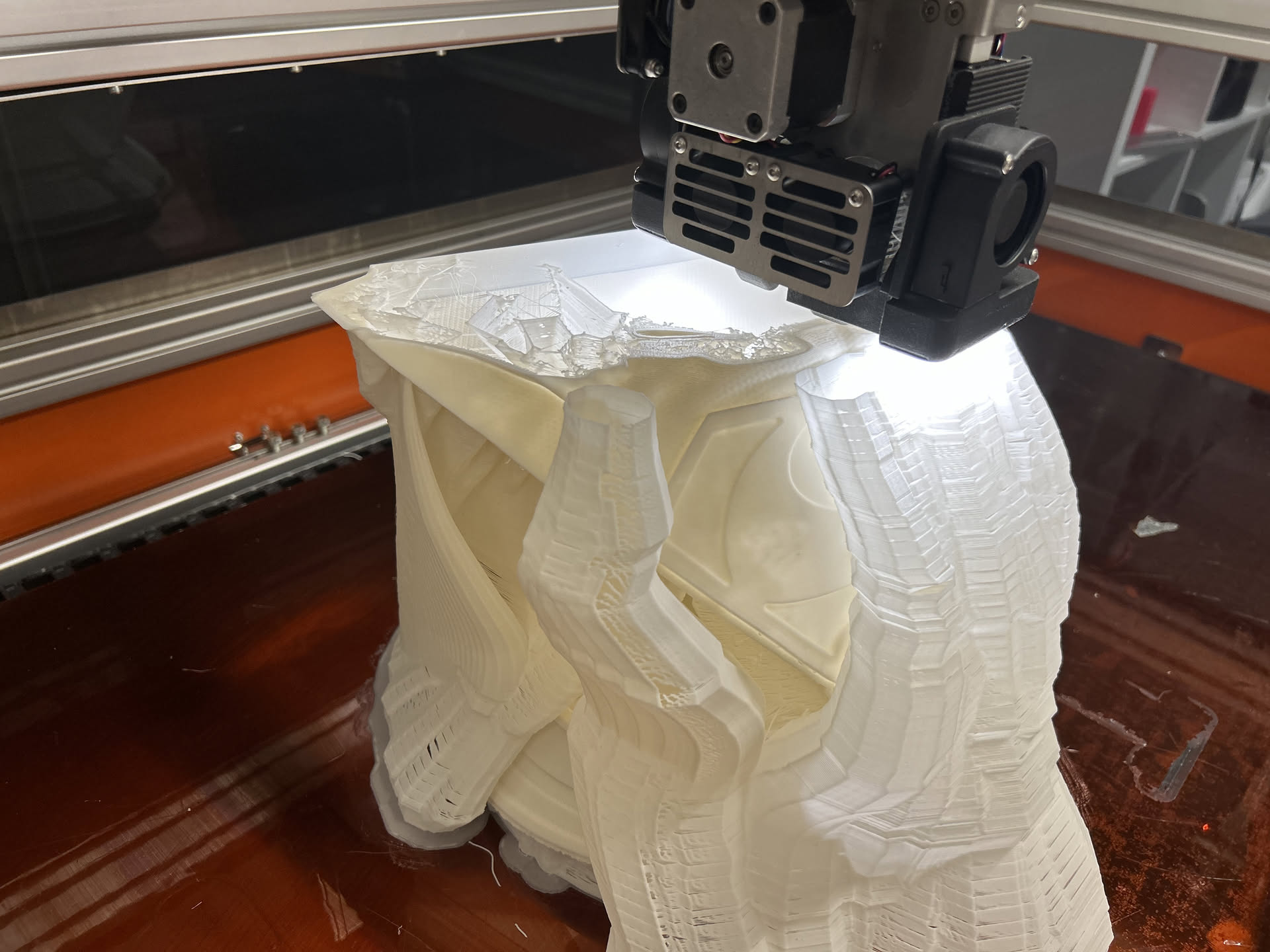

Oversized parts, fixtures, and patterns that exceed typical service bureau limits.

One partner, one conversation — we coordinate production end-to-end and stay responsible for outcomes.

We simplify manufacturing decisions — then execute with accountability.

Relay Manufacturing exists to remove vendor confusion and reduce risk early. You submit files and requirements, we review feasibility and scope, then coordinate production through qualified manufacturing resources.

- Manufacturability review (geometry, constraints, tolerances, risk points)

- Process + material guidance based on function, not vendor bias

- Confident quoting with clear assumptions and scope

- End-to-end coordination from review through delivery

How it works

Clear steps. Clear expectations. Fast feedback — without forcing your project through a template.

- 1Submit files + requirements.

Upload parts and share quantities, timelines, materials, and constraints. - 2We review manufacturability + scope.

We confirm feasibility, identify risks, and align on success criteria. - 3Recommendation + quote.

If it’s a fit, you get a clear scope. If not, you’ll know quickly. - 4Production coordination.

We coordinate execution while staying accountable through delivery. - 5Delivery.

One point of contact, predictable communication, no handoffs.

Why teams use Relay

Many projects are too complex for “checkout-style” quoting — but too small or fast-moving for traditional suppliers. Relay fills that gap with speed and judgment.

We use automation to move fast — but a human review protects you from bad assumptions.

If the job isn’t a fit, we’ll be transparent and help point you to the right path.

One partner who owns communication, coordination, and the final outcome.

Large parts. Real constraints. Real outcomes.

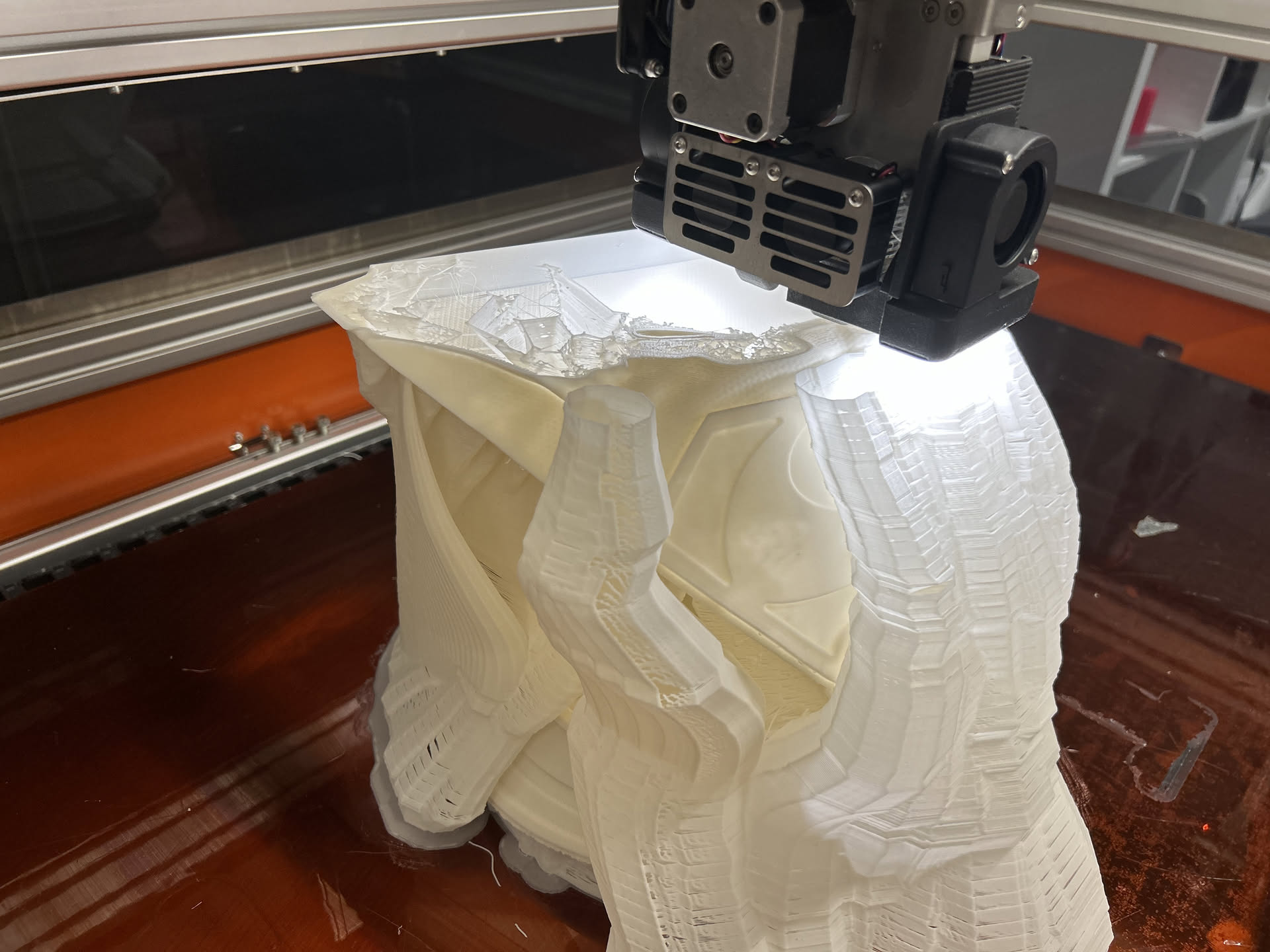

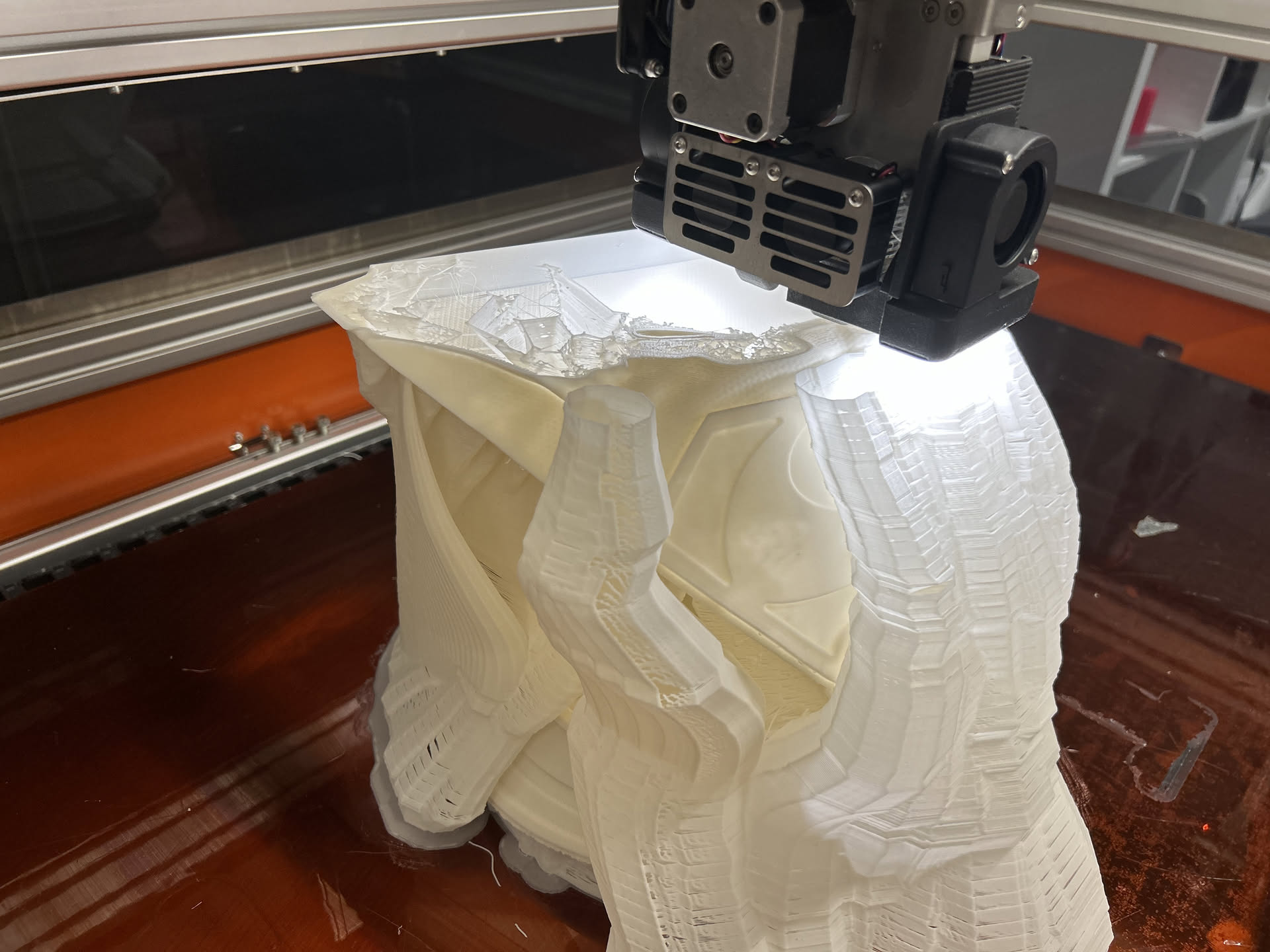

We operate in the world of oversized prototypes, tooling, and low-volume production — where details matter and failure is expensive.

Built for teams who value clarity and reliability

Choose the path that matches what you’re building — we’ll help you validate feasibility and execute predictably.

Functional prototypes and iteration without sourcing chaos.

Patterns, tooling, and geometry validation for castable designs.

Production-ready aids that reduce downtime and speed changeovers.

Large-format parts that exceed typical service bureau limits.

Repeatable parts when traditional tooling isn’t justified yet.

Shapes and assemblies that benefit from additive flexibility.

If you already know exactly what machine you want and only care about price, we may not be the right fit. If you want confidence that your part is being made the right way, we probably are.

Not a black box. Not a handoff.

Relay is built around early risk reduction — the moment where a bad assumption becomes a delay, a scrap, or a redesign. We review your part, define scope clearly, and stay accountable through delivery.

- Transparent fit assessment before quoting

- Clear scope boundaries so expectations match reality

- Direct communication throughout the job

Industrial context — without the hype

We’ve worked around serious equipment and production environments. We focus on the outcome: predictable execution and clear communication.

Start with a technical review — not a checkout.

Submitting a project starts a manufacturing conversation. We review your files, confirm fit, and provide clear next steps before anything moves forward.

No obligation. No sales pressure.